Guitar shielding is one of the most critical parts of a guitar as it covers the internal components and transmission hardware that’s installed within the guitar.

In addition, it covers the strings that are used for the transmission of electromagnetic waves and makes humming or buzzing sounds.

In simpler words, the guitar shielding can directly impact the guitar’s performance, which is why it’s important to be careful about the shielding material.

Copper and aluminum shielding are widely used shielding materials for guitars, so it’s suggested to know the differences to find the right one.

Comparing Guitar Shielding Copper vs Aluminum

| Features | Copper | Aluminum |

|---|---|---|

| Adhesive | Yes | Available in adhesive and non-adhesive forms but the former is hard to find |

| Longevity | Extremely durable | Breaks down easily |

| Soldering | No | Yes (if using non-adhesive tape) |

| Oxidization | No | Yes |

Copper Shielding

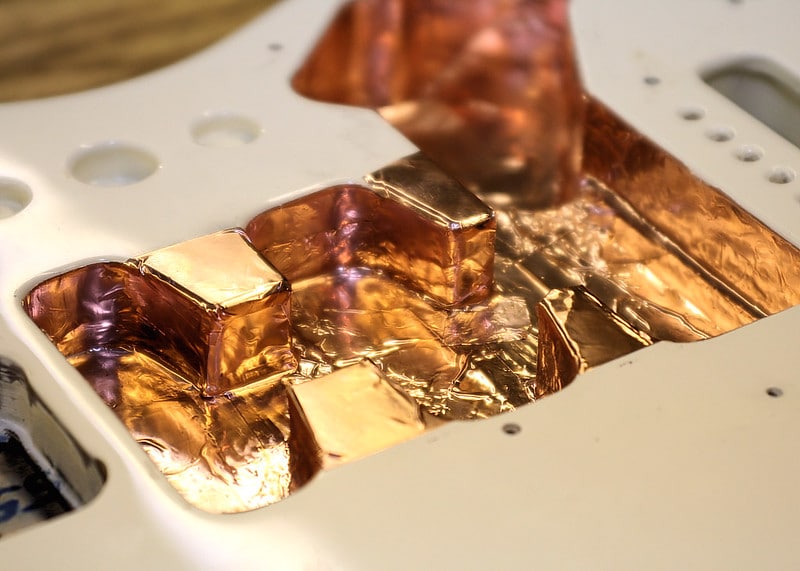

Copper shielding is available in the form of tape, which is applied to the guitar to reduce the hum and enhance the harmonics. Since it’s a more conductive metal and has conductive adhesive, it will be easier for the guitarists to solder it.

The tape can be used for shielding the control cavities and pickups for reducing the radio interference, noise, and hum.

1. Design

The copper shielding is a form of tape with thin copper strips that are backed by adhesives. It is extremely flexible and can be shaped according to the guitar’s curves, which makes it a versatile choice

In addition, it has easier installation. Copper is an extremely conductive material but the shielding tape is available in non-conductive as well as conductive forms.

The conductive tapes can conduct electricity on the bottom and top of the shielding. The conductive tape enables the electrical connections by taping different lengths to each other but its adhesiveness reduces over time.

On the other hand, the non-conductive copper tape has conduction only on one side. The non-conductive copper tape is soldered to create a conducive and reliable joint since it conducts electricity on one side only.

It is widely used for shielding the guitar’s cavities, electromagnetic shielding, paper circuits, wrapping the cables and wires, and as a slug and snail deterrent.

These tapes are available in the form of rolls, which means they can be easily cut to the desired size with regular scissors.

The copper shielding is also available in the form of paint, which has an aerosol texture. These paints provide low-resistance EMI and RFI shielding coating for the electronic housings.

The sprays tend to have a higher adhesion and even surface coating, promising better application. Using copper shielding paint also delivers scratch-resistant features, so the guitars will have an aesthetic appeal as well.

2. Application

When it comes down to the guitar, the electromagnetic interference can be extremely problematic as it disrupts the sound and can damage the internal components of the guitars as they are delicate and cannot handle the excess electronic current.

However, the application of copper shielding will create a grounded and conductive enclosure around the guitar’s case to protect the components and enhance the sound throughput.

The copper shielding tape is coated with a high-end and conductive adhesive, which is also protected by the paper backing. The tapes are resistant to discoloration and oxidation, which means they won’t lose their conductive performance.

The best thing about copper shielding is that it’s suitable for indoor as well as outdoor uses, so you can use the copper-shielded guitars for outdoor concerts as well.

The copper shielding tape or sprays are suitable for Stratocaster, telecaster, and other single-coil guitars because these guitars are prone to making electromagnetic static and exterior interference.

Once applied to the guitar, it will help create the clean bluesy music tones. Also, there is adhesive, which means you don’t need to solder the tape to create a hum-free guitar.

All in all, these tapes are suitable for bass guitars as well as electric guitars.

The copper tape has a pressure-sensitive adhesive, which makes it easy to apply. The adhesive also has conductive particles to ensure a low resistance level between the guitar’s surface and backing.

In addition, the tape is flame retardant, promising improved EMI shielding and grounding. Lastly, the copper shielding has higher endurance and resistance, so it won’t come off but it will be expensive.

Aluminum Guitar Shielding

The aluminum shielding is another tape used for covering the guitar’s internal cavities but can be challenging to solder. This is because there is no conductive adhesive and you need to solder the tape to the guitar’s surface.

However, some aluminum shielding tapes are coated with rubber-based and pressure-sensitive adhesive, but they are extremely hard to find.

Still, aluminum shielding provides an exceptional barrier to vaporization and conforms to the irregular curves and surfaces of the guitar.

1. Design

Aluminum shielding tape is not only suitable for shielding the guitars but offers sufficient thermal insulation as well. Some aluminum tapes also have a paper liner for reliable and convenient use.

These tapes are carefully engineered with metal-foil backing that improves the conductivity and malleability of the tape.

If you need to purchase the aluminum shielding tape for the guitar, it is suggested to use the UL723-certified tape because it is a fire-resistant product and prevents overheating in the guitar.

The aluminum shielding has a temperature range of 248-degrees Fahrenheit to -22-degrees Fahrenheit but it does not perform well if you live in extremely cold areas.

This is because the cold can eliminate the sticking power of the tape, and even if you have soldered it to the guitar, it will start coming off. The aluminum shielding tapes have higher mechanical strength and resistance for weak aging.

The best thing about aluminum shielding tape is the low MVTR level, which means moisture vapor transmission rate, and prevents the damage caused by exposure to moisture.

In addition, it is mold resistant, so your guitar’s wood will be protected from mold-related damage.

When it comes down to the adhesives, it’s hard to find adhesive-backed aluminum shielding but if you find the aluminum shielding with an adhesive, it will have acrylic adhesive.

The adhesive promises easier application because you only need to remove the paperback as compared to the non-adhesive version that has to be soldered.

The paper liner is quite easy to remove and you can also die-cut it to ensure seamless application on the guitar’s curves and corners.

2. Application

When the aluminum shielding tape is applied to the guitar, it is likely to hold up against the temperature fluctuations and exposure to UV light, so you can use the aluminum-shielded guitars for outdoor gigs as well.

Also, it promises thermal stability, preventing the overheating of the guitar’s internal components.

It can be used for sealing the lap joints and works as a vapor seal on the guitar. In addition, aluminum shielding tape is used for joining and sealing the connections as well as air duct seams.

For instance, it has corrosion-resistant properties, so the guitar’s internal hardware will remain intact, even if you play the guitar in outdoor conditions.

In addition, this shielding is extremely conductive, promising better guitar performance. Lastly, it has a higher reflectance that improves the tonal features of the guitar.

On the other hand, the aluminum guitar shielding tape is not a long-term solution as it can easily break down. Still, it can deal with electromagnetic and radio waves pretty fine.

The Final Verdict

Guitar shielding is essential for protecting the integrity of the guitar’s internal cavities and for concealing the open areas of the guitar to make sure there is no humming and buzzing in the sound.

It is suggested to choose copper shielding because it’s more durable and always has an adhesive for easier application.

On the other hand, aluminum shielding is suitable for short-term application only because it breaks down and it will be challenging to find the aluminum shielding that has an adhesive backing.